Flow racks otherwise known as first-in-first-out racks, cartons flow, gravity racks or gravity-fed rack. The flow racks basically enable containers, plastic bins or even loose parts to flow from back to front thanks to the inclined racks where gravity naturally forces parts to be consumed on a first-in-first-out basis. There are five types of flow racks roller racks system that are able to increase the efficiency of your production line and reduce cost in several ways.

Ideal for Kanban and lean manufacturing

The flow racking system are very ideal for Kanban system and Lean manufacturing. These types of structures are able to operate without any stoppage that would typically occur when restocking employee workstation. Implementation of gravity racks therefore increases productivity.

Types

Flow racks can be used as return lines for empty containers as these racks are used to move empty containers from the production side to the supply where the necessary parts can be replenished. This increases efficiency as the employees do not need to move to the production zone to load or unload containers.

Supermarket or marketplace racks are usually high-density flow racks which are strategically located on the production floor so as to create mini stockrooms. They are able to reduce transportation time between the production line and the storage area.

As much as most of the flow racks are designed to be in a straight line some of them are built to be in a L-shape. This type of configuration aids in reducing the need of workers making repetitive and unnecessary movements. They are widely used in automotive industry to bring parts as close as possible to the operator’s machine. They can be used in any type of industry to improve workers efficiency and safety.

-

Read MoreQuick View

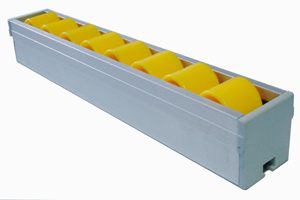

Read MoreQuick ViewCarton Flow Racks

Carton Flow Racks

Flow track =ABS wheels + steel channel

1) Made of high quality ABS and steel channel.

2) Low friction and good strike-proof.

3) The roller wheels can resist acid, alkali and moisture, can be used in humid environment.

4) The flanged profile of the roller wheel is made of zinc-coated steel to ensure Strong duration.

5) Different size is available and have many colors wheel for your choice. -

Read MoreQuick View

Read MoreQuick ViewRoller racking

Roller Track racks

Roller rack can dramatically improve warehouse efficiency by organizing

product and rotating stock automatically. Long, straight, dedicated lanes

maintain product organization and keep labor costs down. Storage space

can be increased up to 60% by using a minimum of 22% less floor space,

thereby keeping building costs down. Typically, Carton Flow systems use

about half the floor space that standard pallet rack occupies and the difference

can be more dramatic with multi-level systems . The simplicity of gravity driven

systems requires less capital than maintenance-prone automated systems.

-

Read MoreQuick View

Read MoreQuick ViewRoller Tracks / Flow tracks

Roller Tracks / Flow tracks

Flow track =ABS wheels + steel channel

1) Made of high quality ABS and steel channel

2) Low friction and good strike-proof

3) The roller wheels can resist acid, alkali and moisture, can be used in humid environment

4) The flanged profile of the roller wheel is made of zinc-coated steel to ensure Strong duration

5) Different size is available and have many colors wheel for your choice.

English

English 简体中文

简体中文